Catching on: Biogas production is starting to find traction in South Africa with companies such as Elgin Fruit Juices and PepsiCo’s Simba chips plant as well as small-scale farmers and schools. Photo: Supplied

Cutting greenhouse gases from energy production and transport tends to take centre stage when we talk about fighting climate change, but circular economies — keeping materials in use for as long as possible through reuse, recycling, repair and design innovation — is just as important.

Roughly 45% of global greenhouse gas emissions come from the way we produce and use materials, according to a 2019 report titled Completing the Picture: How the Circular Economy Tackles Climate Change, by the Ellen MacArthur Foundation and Material Economics.

The paper illustrates how preventing and reducing waste, regenerating farmland and keeping materials in use can reduce carbon emissions by 9.3 billion tonnes. “That is equivalent to eliminating current emissions from all forms of transport globally,” it states.

Non-energy or transport-related emissions are primarily from the production of materials such as cement, steel, plastic and aluminium, as well as from agriculture and food production. It also includes emissions from organic waste in landfills that emit methane, a potent greenhouse gas that has a much stronger warming effect than carbon dioxide emitted by cars, for instance.

These fall under huge, fast-growing economic sectors, so reducing their effect is essential in the battle against climate change, says Good Governance Africa’s director of research, Ross Harvey.

“We have overstepped six of our nine planetary boundaries (thresholds for Earth’s stability). The six are: climate change, biodiversity loss, deforestation, nitrogen and phosphorus pollution, plastics, chemicals, synthetic pollution and freshwater change. The remaining boundaries, some close to being crossed, are: ocean acidification, atmospheric aerosol loading and stratospheric ozone depletion.

“Re-use, recycling and detoxification in systems-based circular economies can drastically reduce the load on these planetary boundaries, and aid biodiversity recovery,” he says.

Circular economies were a dominant theme at this year’s Future of Sustainability conference, a platform for businesses, entrepreneurs, policymakers and industry experts to discuss sustainability strategies. Various ways to create circular economies were explored, including biogas production, which is steadily gaining traction in South Africa’s renewable energy landscape.

Forerunners in the biogas sector include Bio2Watt’s large-scale biogas plants in Bronkhorstspruit, Gauteng, and the Western Cape (Cape Dairy Biogas Plant), Cape Town Biogas, and PepsiCo’s Simba chips plant in Johannesburg. Smaller plants have been set up by Elgin Fruit Juices and various piggeries (such as Global Northern KZN Piggery), while hundreds of small-scale and micro-scale biogas plants have been constructed mainly by small farmers and schools.

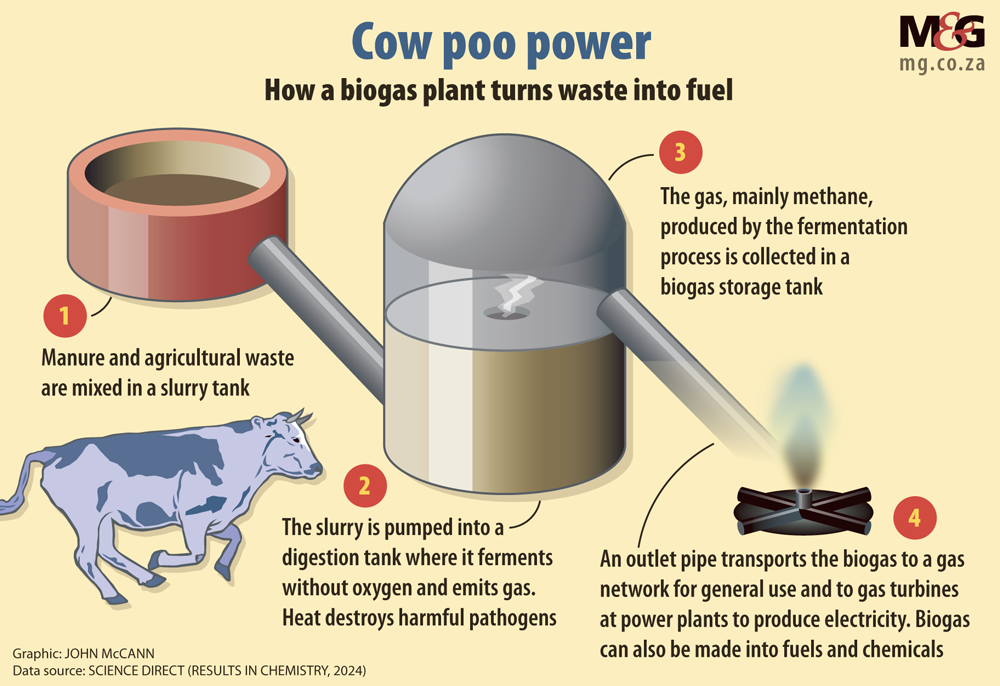

Biogas production works by breaking down organic material such as food waste, manure and sewage to produce a methane-rich renewable fuel and digestate (a nutrient-rich slurry). The biogas can be used to generate electricity, replacing fossil fuels and the digestate can be used for fertiliser. Biogas can also be used for cooking (piped to a biogas-compatible cooker) and heating (used in gas geysers and heaters).

Biogas deserves far more serious attention than it is receiving, says Gordon Ayres, secretary of the Southern Africa Biogas Industry Association.

“The benefits are huge. A community with limited services could, through some clever investment, clean up a problematic waste, heat itself and create small food gardens which would produce organic food.

“On a larger scale, our municipalities are struggling with organic waste. Landfills are full, and no new licences are being issued; wastewater plants are oversubscribed by a factor of 150% or higher. By running waste through a biogas system, it reduces in volume by up to 97%.

“Farmers crippled by costs of fertiliser, chemically damaged soils and mine-damaged soils can also be remediated with biogas fertiliser. Just the sheer number of jobs that are waiting in the industry is huge; from people building plants, transporting feedstock, involved in gas and gas equipment, farmers who open up unused fields because it becomes profitable to do so and even onwards as biogas is an easy conversion to hydrogen.”

Constraints on biogas production arise from a lack of knowledge, skills and resources needed at municipal level to activate this sector, compounded by the silo effect of having various departments dealing with waste (such as environment, planning and energy), said Ayres.

Added to this is the problem of resistance from established waste management entities, including patronage networks, that perceive biogas initiatives as a threat to their operations and revenue streams. This was noted in a 2023 report by the International Energy Agency Bioenergy: Task 36, which found that this opposition creates an environment resistant to the integration of innovative solutions like biogas.

There was “noteworthy opposition from certain sectors of society that oppose any form of thermal waste treatment. Another element relating to the waste hierarchy is that landfilling is seen as the best solution due to the ease of disposal and the cost feasibility with low gate fees,” the report said.

Conversely, in the mining industry, despite being traditionally excluded from circular economy considerations because of being an inherently extractive practice, circular economy principles — reducing energy, water and material consumption in the mining process and diversifying minerals via recycling and recovery from waste streams such as tailings — are now in strong focus.

Julie Courtnage, executive director of the Mandela Mining Precinct, said: “The circular economy has found considerable traction with business and government over the past few years as a way of sustainably managing resources, reducing costs and improving global competitiveness.”

The Precinct launched the South African Circular Minerals and Metals Initiative with the support of the department of science and innovation’s Circular Innovation South Africa fund last year.

To appreciate the importance of circular economies, consider the wastefulness of typically linear production lines in the food manufacturing sector. An example, cited at the sustainability conference by Neissan Besharati, research director of sustainability, ESG, impact and circular economy at the Gordon Institute of Business Science, is the meat industry.

“First, a cow contributes more damaging methane emissions than your car. Then the meat from that cow is often put on planes or shipped and exported to Europe. There, it is made into burgers and sent back to our fast-food outlets here. Throughout this process, there is refrigeration and transport. A lot of energy is used. And that makes you wonder, is that really necessary?”

This example illustrates the importance of shortening supply chains by centralising production and processing to regional hubs, which in turn creates local jobs and stimulates small and medium enterprises while building economic self-sufficiency. Waste also becomes a resource locally, for example, scrap metal or used glass can be recaptured and integrated into production. In Gauteng, waste glass collected by local buy-back centres is melted down and reused by regional glass manufacturers such as Consol, preventing that glass from leaking out of the system as landfill or export waste.

Waste recycling is particularly important in a circular economy, because here is where carbon-heavy extracting, refining and transporting can be significantly reduced or averted altogether. Recycling aluminium saves up to 95% of the energy needed to produce it from bauxite, for example, and recycling glass saves about 30% of the energy versus using raw sand, soda ash and limestone to create new glass.

If one considers just how energy-intensive aluminium smelting is, or how much ecological damage illegal sand mining does, then it’s clear that every tonne of recycled material avoids tonnes of CO2 from extraction and processing. It undermines the logic of extraction, production and consumption that is accelerating our sixth extinction.

Ultimately, circular economies are not only about recycling and repurposing, they’re about rethinking how economies function. They decouple economic growth from resource use and emissions, making them a powerful tool for deep, long-term climate action.

Helen Grange is a writer and sub-editor at Good Governance Africa.

Crédito: Link de origem